Colloid-A-Tron Description

Download Specifications Sheet PDF

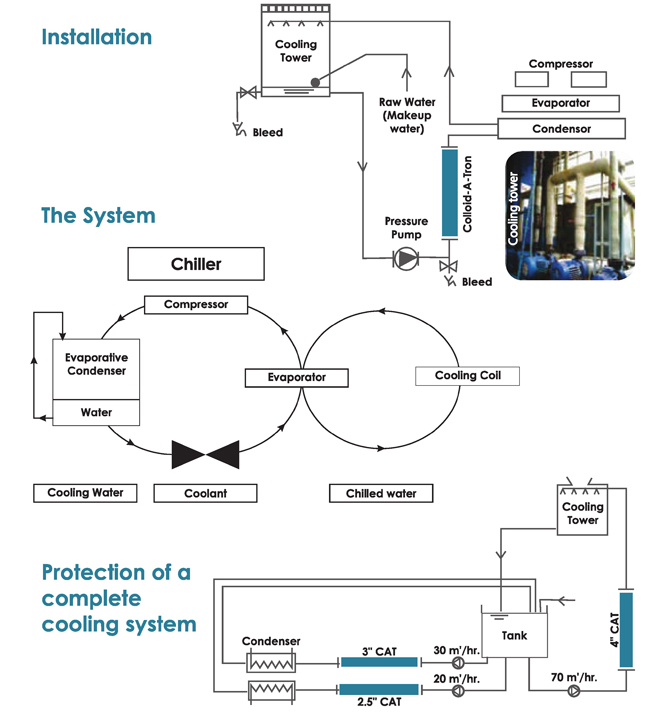

Specially designed for heavy industry and cooling towers.

The Colloid-A-Tron is a unique lime-scale prevention system which consists of a non-sacrificial lead free catalytic core made from a special alloy housed within a non-reactive stainless steel (316) tube. Colloid-A-Tron provides the ideal solution to the problems associated with hard water scaling

Industrial / Commercial Applications

- Humidifiers

- Compressors

- Condensers

- Air Conditioning

- Air Washers, Scrubbers

- Cooling Rods Felt Washing

- Boilers, Low Pressure Calorifiers

- Injection Molding Machines

- Sea Water cooling circuits

- Ice Makers

- Extruders

- Friction Brakes

- Grinders and Mixers

- injection molding machines

- Presses

- Heat exchanger

- Hot Water Heaters

- Cooling Tower

- Vacuum Pumps

- sea water cooling circuits

The system how does it work…?

Colloid-A-Tron (CAT) units are installed in 40 countries on 5 continents. Many leading companies have used CAT treatment in countries across the world such as Ford, Bush Beans, Guinness, ICI, Nestle, Carlsberg, Renault and Coca-Cola. Since 1973 hundreds of thousands of customers have benefitted from the installation of the Colloid-A-Tron.

Colloid-A-Tron Technology

Colloid-A-Tron consists of a pipe with a special

alloy core inserted inside. The unit comes in

different sizes, threaded or flanged as

required. In order to prevent scale from forming

in a system or a specific piece of equipment a

Colloid-A-Tron is installed replacing a section

of feed pipe.

The Colloid-A-Tron operates as a catalyst using the pH rise generated by the alloy to trigger precipitation of calcium carbonate in the bulk of the water forming stable crystals. The result is a water that has less calcium and carbon available in solution. That solution has the characteristics of a softer water and therefore does not deposit scale as it passes through the system.

The problem

The formation of scale caused by hard water in pipework and equipment is costly and seriously reduces operating effectiveness. Scaling and its removal manually or by chemicals can cause damage to equipment. Generally the application of chemicals has been the traditional method of handling these problems – however increasing environmental pressures and restrictions are causing responsible industries and plant operators to look for alternative methods. The Fluid Dynamics method of preventing hard water scale is tested and approved by many leading universities and institutions around the world.

The answer

Colloid-A-Tron provides the ideal solution to the problems associated with hard water scaling;

- Totally safe for the environment

- Constant supply of treated water

- Requires no shutdowns for maintenance

- Uses no energy or electricity

- Product life expectancy 15 – 25 years

- Ten year part replacement warranty*

- Fluid Dynamics is the world leader in non-chemical water treatment systems.

*Warranty is pro rata refurbishment/replacement for materials failure or defect